Coatings for Tank Protection and Chemical Industry

Even the everyday environmental influences such as wind, rain and atmospheric gases have an aggressive effect on steel. Unprotected steel corrodes so massively due to the chemical, electrochemical and mechanical influences of the environment that the material can lose essential functions within a few months: statics, protection and tightness are then no longer guaranteed. Particularly high demands are placed on corrosion protection in all areas of the chemical industry and in plant construction. Pipes, pipe bridges, columns and tanks are sometimes exposed to extreme stresses and must still be able to maintain their function permanently and safely – in the worst case, there might be threat of pitting and accidents.

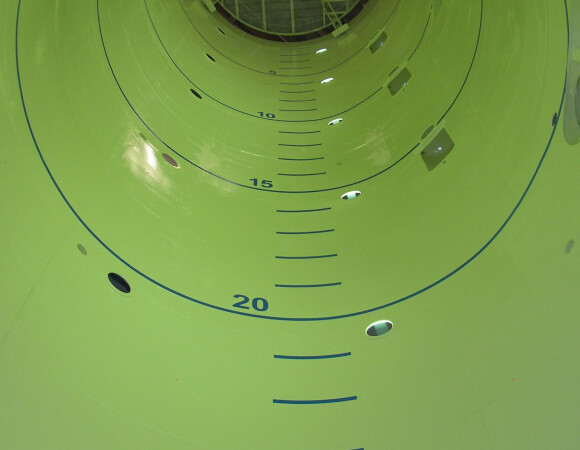

In addition to the general weather influences, a chemically contaminated atmosphere and condensed water often affect the outdoor area of chemical plants. Inside containers or pipes, a variety of sometimes challenging bulk materials can attack the steel. Flammable liquids, fats and oils, aggressive chemicals, acids and alkalis, industrial or municipal waste water, agricultural substrates or even food – they all have a decisive influence on the service life of the container if in direct contact with the inside. This is a challenge for the corrosion protection coating.