In order to be able to assess the behaviour of the existing coating and to define a binding execution standard for the coating work, test surfaces were created in advance. It turned out that the old coating was still completely intact and an intermediate coating was therefore no longer required. This was confirmed by the adhesion values of a destructive test. Against this background, it was decided together with Sherwin-Williams to adapt the originally planned coating system.

Home game for Sherwin-Williams Coatings Deutschland GmbH

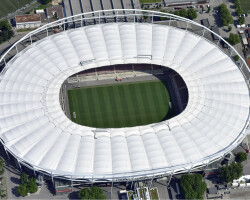

Stromberg Oberflächentechnik GmbH & Co. KG, which is familiar with Sherwin-William product range, carried out the corrosion protection work. A total of 16,500 m2 of steel were recoated. "For Sherwin-Williams Coatings Deutschland GmbH with its plant in Vaihingen/Enz, the supply of corrosion protection products for the VfB Stuttgart Arena is an important home game," said Alexander Möller-Battling, Project Manager at Sherwin-Williams.

For the pre-treatment of the surface before the coating, 40 steel supports and all compression rings were swept, i.e. blasted at reduced pressure from 3 to 4 bar. The adhering parts of the old coating could thus be roughened and loose material removed.

Areas that had to be swept down to the steel were given a first coat of primer in advance. Subsequently, a 2-component epoxy resin-based primer coat was applied, namely the low-solvent Macropoxy® Primer HE N in the shade of sand yellow. The surface-tolerant primer can be processed very well even at low temperatures down to +5 °C, is characterized by fast initial drying and through hardening and is resistant to weathering and mechanical loads. Especially due to layer thicknesses of 150 to 200 microns, a high degree of protection against corrosion is already achieved. The primer was directly followed by two layers of the Acrolon® 2330 top coat. The 2-component acrylic polyurethane coating is particularly resistant to weather with stable gloss and colour, ensuring an appealing look for many years. Acrolon® 2330 is available in RAL and NCS shades. Stadion NeckarPark GmbH & Co. KG chose the NCS colour from both colour variations. The entire coating work was carried out in a confined space at a height of up to 50 metres. The application of all layers was done by roller, with the exception of the corners and edges. These were done with a long-handled, angled, round-tip brush.

Renovation went faster than planned

That the renewal of the roofing sheets could begin punctually at the start of the summer football break, the corrosion protection work took place during the ongoing season of VfB Stuttgart, back then in the second division of the Bundesliga. To protect the coating, the columns in the spectator areas were enclosed and monitored one day before each game. An additional challenge was the twisted steel compression rings of the stadium, which the scaffolding contractor had to compensate so that the corrosion protection work could be carried out safely and professionally.

Corrosion protection coatings from Sherwin-Williams are characterised by a high spreading rate in material use and particularly fast processing. "Six months were foreseen for the renovation. We were finished two weeks before the agreed date – in time for the season finale and the promotion of VfB back to the first division of the Bundesliga", recalls Dirk Schroer, Project Manager Corrosion Protection at Stromberg. The durability of the new coating is now more than 15 years once again.