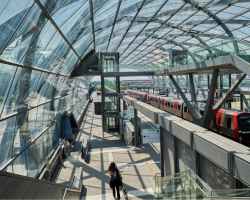

Hamburg’s HafenCity is the most important urban expansion area of the metropolitan region. In the east, the new “Elbbrücken” quarter with living space, offices and Hamburg’s first skyscraper is currently being built there. In future, the new underground and suburban railway station will be used by up to 20,000 passengers daily. This includes not only the inhabitants of Hamburg, but also numerous tourists. The functional and architectural demands placed on the construction of the new transport infrastructure are correspondingly high, because the underground railway runs the last metres above ground. From the high glazed station as well as at the transport hub itself, passengers can see Hamburg’s landmarks such as the Elbphilharmonie, Michel and Elbe.

Award-winning platform roofing made of steel and glass

The construction of the platform roof for the underground as well as for the suburban railway station consists of an external, curved structure made of steel. Below it is the suspended glazing of the hall roof. The steel arches span the platforms diagonally and are twisted. The executing steel construction company SEH Engineering GmbH developed special bending and assembly devices for this purpose in order to precisely implement the profile curve of the welded, double-T-shaped and interleaved arched trusses. At the granting of the Steel Innovation Award 2018 of the Wirtschaftsvereinigung Stahl (Steel Association), SEH Engineering GmbH was awarded the 1st prize in the category steel in construction for the construction of the steel roof. There are three levels in the hall of the underground station. There, passengers have access to the trains and possibilities to cross the tracks safely. The underground station is connected to the future suburban railway station via a pedestrian bridge, the so-called “Skywalk”. Deutsche Bahn is the operator of the suburban railway line and opened the new station in December 2019.

Unique combination of corrosion and fire protection

The entire steel superstructure of the suburban and underground railway station is protected against corrosion by a coating system from Sherwin-Williams in accordance with TL/TP-KOR steel structures, sheet 87. This consists of the primer Zinc Clad® R, the edge protection Macropoxy® EG Phosphate (new product: Macropoxy® EG Phosphate N) and the intermediate coat Macropoxy® EG-1 (new product: Macropoxy® EG-1 Plus). The final top coat Acrolon® EG-4 was applied in the shade DB 702. The soffits of the track superstructure and the tree supports of the underground railway station are provided with a 2-component fire protection system from Sherwin-Williams: In order to increase the fire resistance duration of the load-bearing components, the FIRETEX® Platinum intumescent coating was applied over the Zinc Clad® R primer and the Macropoxy® EG Phosphate edge protection. As the final top coat, Acrolon® EG-4 in the shade DB 703 according to sheet 87 was also used here. The steel superstructure of the “Elbbrücken” underground station in Hamburg is thus one of the first steel structures to be completely equipped with a corrosion protection system from Sherwin-Williams according to sheet 87 in combination with a Sherwin-Williams fire protection system. Both systems from the manufacturer are compatible with each other and therefore unique on the market in this combination capability. The result is significant time savings during production at the factory and on the building site, as no different primer and top coats need to be used.

Completion of protective and sealing systems on the building site

The factory pre-coating of the steel elements was carried out by Surface Protection GmbH, a subsidiary of SEH Engineering GmbH. Special craftsmanship was required during the coating work on the round tree supports of the Skywalk in order to achieve a uniform layer thickness of the material. The welded joints were brought up to the level of the factory coating on site in accordance with the requirements of ZTV-ING, Part 4, Section 3 – Corrosion protection of steel structures with the primer, the edge protection and the intermediate coat. Finally, the entire steel structure was coated with the Acrolon® EG-4 top coat in the DB 702 shade. The coating of the top sides of the cover plates in the area of the track crossing and the pedestrian bridges was carried out in accordance with ZTV-ING, Part 7, Section 4 – Bridge floorings on steel surfaces. A total of about 12,000 m2 of steel structures are protected with systems from Sherwin-Williams at the new “Elbbrücken” station.

Consulting services of the Sherwin-Williams experts

The specialist consultants from Sherwin-Williams were already involved in the corrosion and fire protection planning of the construction project and supported the planners and processors with their knowledge. The coating work at the plant and on the building site was accompanied by Sherwn-Williams application technicians. The services relating to the construction project – from the planning to the execution at the plant and on the building site – were highly valued by the client, the contractor and their applicators during the construction of the new Elbbrücken stations in Hamburg.